Chemical Composition of Foam Materials

Foam materials are versatile in their applications, serving industries ranging from furniture to automotive. Understanding the chemical composition of these materials, particularly polyurethane foam, is essential for appreciating their wide array of uses and properties. Polyurethane foam, with its chemical formula C27H36N2O10, is a staple in modern manufacturing due to its unique structure, physical characteristics, and ease of production. This article provides a comprehensive overview of polyurethane foam, exploring its structure, properties, and common applications. Additionally, we address frequently asked questions regarding its safety, production, and uses, offering valuable insights for both professionals and curious enthusiasts eager to learn more about this fascinating material.

Table of Contents

-

What is Polyurethane Foam?

-

Polyurethane Foam Structure – C27H36N2O10

-

Physical Properties of Polyurethane Foam – C27H36N2O10

-

Chemical Properties of Polyurethane Foam – C27H36N2O10

-

Uses of Polyurethane Foam – C27H36N2O10

-

Frequently Asked Questions

What is Polyurethane Foam?

Polyurethane foam is a polymer composed of organic units joined by urethane links. It is one of the most versatile materials available, recognized for its flexibility and resilience. Introduced in the late 1930s, polyurethane foam has become a foundational material in manufacturing due to its adaptability and robustness.

There are two primary types of polyurethane foam: flexible and rigid. Flexible polyurethane foam is soft, compressible, and used primarily in household items such as mattresses, furniture, and carpets. Rigid foam, on the other hand, is used in insulation panels, specialty packaging, and thermal storage tanks due to its excellent insulating properties.

The foam can also be produced with varying densities and hardness levels, making it suitable for different mechanical and thermal requirements. Polyurethane’s extensive applications are a testament to its unique combination of physical properties and structural flexibility.

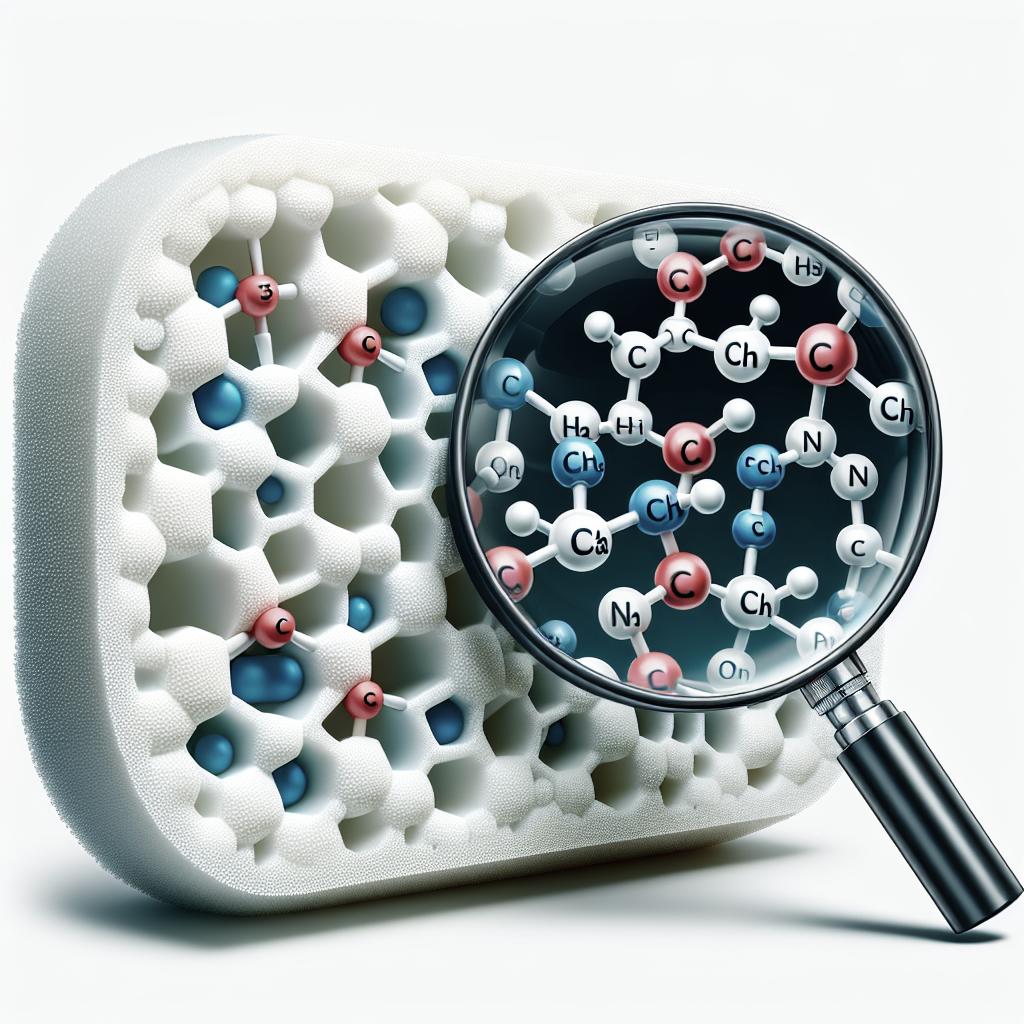

Polyurethane Foam Structure – C27H36N2O10

The structural foundation of polyurethane foam is its chemical formula, C27H36N2O10, which provides insights into its chemical makeup and resultant capabilities. This complex organic compound consists of carbon (C), hydrogen (H), nitrogen (N), and oxygen (O) atoms, artfully bonded to create a robust yet flexible network.

Polyurethane is produced through a chemical reaction known as polymerization, where monomers containing isocyanate groups react with polyols. The resulting compound forms a matrix that can be manipulated into various forms of foam, versatile enough for different industrial applications. Its cellular structure also varies, allowing for greater customization in terms of porosity and density.

This unique arrangement of atomic groups allows polyurethane foam to achieve a delicate balance between rigidity and flexibility, making it a preferred choice for products demanding specific performance criteria such as cushioning, insulation, and even soundproofing.

Physical Properties of Polyurethane Foam – C27H36N2O10

Polyurethane foam is praised for its outstanding compression strength, elasticity, and high resistance to abrasion. These properties make it suitable for various applications, from protective packaging to furniture cushioning. Flexible polyurethane foam, in particular, can rebound quickly after being compressed, maintaining its shape and functionality over time.

Another notable property is its lightweight nature. Despite its strength and resilience, polyurethane foam remains remarkably light, which contributes to its widespread use in industries that prioritize weight savings, such as the automotive and aerospace sectors.

Moreover, the material boasts impressive thermal and acoustic insulation properties. Rigid polyurethane foam is particularly valued for its low thermal conductivity, which effectively slows down heat transfer, thus providing excellent insulation both in construction and appliances. Its sound-absorbing capabilities are also leveraged in environments requiring noise reduction, such as recording studios.

Chemical Properties of Polyurethane Foam – C27H36N2O10

Polyurethane foam is chemically stable under normal conditions, resistant to many chemical agents, including oils, greases, and solvents. This inherent chemical resistance prevents degradation over time, making polyurethane foam an enduring material option in numerous environments.

However, it is important to note that when exposed to high temperatures or ultraviolet light over extended periods, polyurethane materials can degrade. Additives such as flame retardants and stabilizers are often incorporated into formulations to enhance resistance to extreme conditions and prolong the material’s lifespan.

Additionally, polyurethane foam is versatile in its formulation. By adjusting the type and proportion of raw materials used, manufacturers can produce foams with varying chemical properties, such as altering the resistance to chemicals or adjusting hardness levels. This chemical customizability is a major factor in the widespread adoption of polyurethane foam across various industries.

Uses of Polyurethane Foam – C27H36N2O10

The applications of polyurethane foam are vast and diverse. In the furniture industry, it is the material of choice for upholstered products like sofas and chairs, owing to its comfort and durability. In insulation, rigid polyurethane foam helps in maintaining temperatures within buildings and vehicles, providing energy-efficient solutions.

In automotive applications, its lightweight yet robust structure contributes to reducing vehicle weight, thereby improving fuel efficiency while maintaining safety and comfort. It is also used in car seats and headrests to offer enhanced comfort and safety.

Beyond these sectors, polyurethane foam serves critical roles in soundproofing, packaging for fragile goods, and even medical applications, including custom-molded orthotics and prosthetics. Its versatility and ability to be economically produced on a large scale make it indispensable in modern manufacturing.

Frequently Asked Questions

What are the uses of polyurethane foam?

Polyurethane foam finds applications across various domains. It is extensively used in manufacturing furniture, bedding, car parts, and insulation materials. Furthermore, its lightweight and insulating properties make it ideal for automotive and construction industries. In everyday items, polyurethane foam is found in mattresses, car seats, and sponges. Its adaptability further extends its uses into fields such as medical devices and soundproofing materials.

How is polyurethane produced?

Polyurethane is produced through a chemical reaction between a polyol and a diisocyanate. This polymerization process results in a versatile foam material. The production involves blending the raw materials, which are subsequently expanded with the aid of blowing agents. The foam can be molded into different shapes and sizes, allowing it to be customized for particular uses. Catalysts and additives can be included in the formulation to tailor the foam’s properties such as density, elasticity, and fire resistance.

Is polyurethane toxic?

In its final form, polyurethane foam is generally considered non-toxic and safe for use, being prevalent in household and personal applications. However, it is important to handle its raw materials with care during the manufacturing process, as isocyanates and other volatile organic compounds can pose health risks if not managed properly. Proper ventilation and personal protective equipment are essential during production to ensure safety.

Final Thoughts

| Aspect | Description |

|---|---|

| Origin and Types | Polyurethane foam originates from polyurethane, primarily in flexible and rigid forms. |

| Chemical Structure | Consists of complex organic compounds with a structural formula of C27H36N2O10. |

| Physical Properties | Characterized by resilience, lightweight, and excellent insulation capabilities. |

| Chemical Properties | Stable with high resistance to chemicals; customizable with additives for various properties. |

| Applications | Used widely in furniture, automotive, construction, and many other sectors. |