Flexible Foam vs. Rigid Foam: A Comprehensive Guide

Choosing the right type of insulation can make all the difference in energy efficiency, cost-effectiveness, and overall comfort of a building. In this article, we delve into the key differences and similarities between flexible and rigid polyurethane (PU) foams. We’ll explore the characteristics, applications, and insulative properties of both types of foams, while also comparing them to fiberglass insulation in various aspects such as cost, ease of installation, and durability. By breaking down these facets, we’ll offer you insightful guidance on making the best informed decision for your insulation needs.

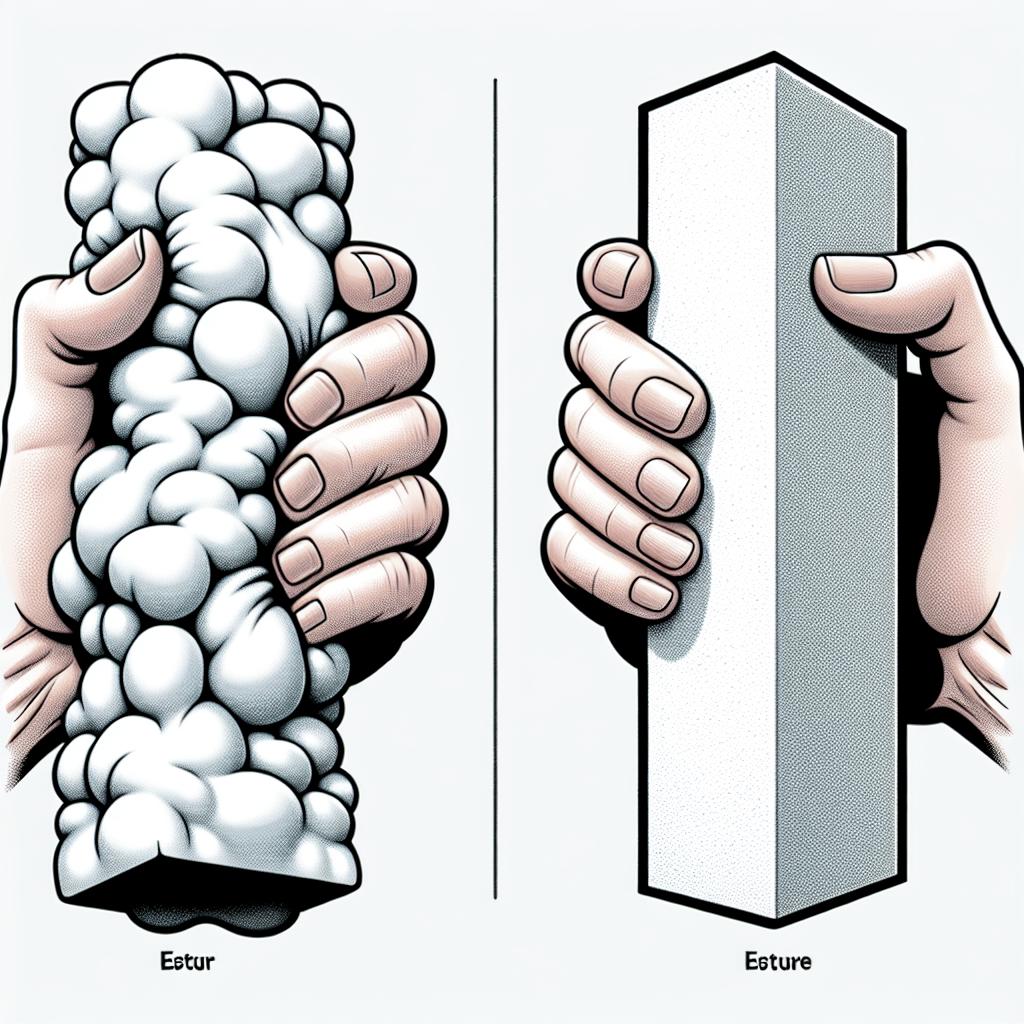

Flexible Polyurethane (PU) Foams

Flexible polyurethane foams are commonly used in applications where cushioning and comfort are priorities. They are known for their elasticity, resilience, and ability to contour to various shapes. This type of foam is predominantly used in furniture, bedding, automotive seating, and packaging due to its shock-absorbing capabilities.

The open-cell structure of flexible PU foams allows for good airflow and moisture drainage, making them ideal for environments prone to humidity. Despite offering less thermal insulation compared to rigid foams, their versatility in design and comfort-oriented applications solidify their place in the market.

Rigid Polyurethane (PU) Foams

Rigid polyurethane foams are primarily used for insulation purposes. Their closed-cell structure offers excellent thermal insulation, moisture resistance, and structural support, making them a go-to choice for construction and industrial applications. Its thermal properties help reduce energy costs by preventing heat transfer.

Aside from insulation, rigid foams are used in sandwich panels, roof and wall insulation systems, and even in floatation devices due to their buoyancy. The structural rigidity and high compressive strength also make them a valuable material where structural stability is key.

Rigid Foam vs. Fiberglass Insulation: Major Differences

Rigid Foam Insulation

Rigid foam insulation is predominantly used for its excellent thermal performance and toughness. Composed of materials like polystyrene, polyurethane or polyisocyanurate, rigid foam exhibits impressive R-values and moisture resistance. Its application spans foundation walls, roof panels, and more, effectively reducing thermal bridging.

One of the distinct advantages of rigid foam insulation is its versatility in different climates, given its superior ability to prevent moisture accumulation. This quality ensures longer lifespan and consistent performance, making it a preferred choice where insulation demands are high.

Fiberglass Insulation

Fiberglass insulation remains a popular choice for its cost-effectiveness and ease of installation. It consists of natural ingredients like sand and recycled glass, bound together into fine fibers. This composition makes fiberglass a highly accessible insulation option for walls, attics, and floors.

While fiberglass performs adequately in moderate climates, its overall R-value is generally lower than that of rigid foams. Additionally, its porous nature makes it less resistant to moisture, which can lead to mold growth and reduced performance over time if not properly protected.

Applications

Rigid Foam Insulation

Rigid foam insulation is utilized in various applications including external wall sheathing and basement and foundation insulation. Its structural strength makes it apt for use under load-bearing concrete slabs and roofs, providing a dual benefit of insulation and added support.

Commercial buildings and residential constructions both benefit from the thermal efficiency of rigid foam. It can be customized into different shapes and thicknesses to meet specific architectural and engineering requirements, enhancing its adaptability across different building projects.

Fiberglass Insulation

Fiberglass insulation is primarily used in residential settings due to its affordability and easy installation. It is commonly found in residential walls, attics, and crawl spaces where the spaces are more uniform and accessible.

Being lightweight, fiberglass is easy to handle and cut to size, making it ideal for retrofitting projects and new constructions alike. However, it often requires a vapor barrier to protect against moisture ingress, particularly in areas with high humidity levels.

R-Values

Rigid Foam Insulation

The R-value of rigid foam insulation is one of its most significant advantages. Depending on the material, rigid foam insulation can provide R-values ranging from 3.8 to 8.0 per inch, significantly higher than that of fiberglass. This allows for thinner layers of insulation while achieving similar thermal performance.

Such high R-values make rigid foam an ideal choice for applications requiring maximum insulation effectiveness with minimum space consumption. It facilitates energy savings by reducing thermal bridging and ensuring a continuous insulation barrier.

Fiberglass Insulation

In comparison, fiberglass insulation offers R-values between 2.2 to 3.8 per inch, often necessitating thicker layers to match the performance of rigid foams. Despite this, fiberglass remains effective as an insulator, particularly in moderate climate zones.

Its fibrous nature allows for traps of air within its structure, which contributes to its insulation capabilities. However, the overall efficiency of fiberglass can be compromised in the presence of moisture or installation issues, such as compression or gaps.

Foam Board vs. Fiberglass Insulation Cost

Cost is a key consideration in insulation choices. On average, rigid foam insulation tends to be more expensive than fiberglass. However, its higher initial cost is often justified by superior R-values and longer-lasting performance, which can lead to energy cost savings over time.

Fiberglass offers a lower upfront cost and can be more economical for large coverage areas where thermal performance demands are moderate. When assessing cost, it is vital to factor in installation expenses and potential long-term savings provided by the energy efficiency of the insulation material.

Ease of Installation

Rigid Foam Insulation

Installing rigid foam insulation demands precision and can be labor-intensive, especially when it involves cutting boards to fit various spaces and sealing joints to prevent thermal bridging. Skilled labor is often required to ensure proper installation, but the result is a highly effective insulating barrier.

Innovations in installation techniques aim to simplify the process, offering pre-scored panels or interlocking systems designed to reduce installation time and effort, addressing one of the primary concerns associated with this insulation type.

Fiberglass Insulation

Fiberglass insulation is typically easier to install compared to rigid foam. It is flexible, can be shaped to fit snugly against structural components, and requires minimal tools for installation. This makes it an attractive option for DIY projects or quick renovations.

However, proper safety precautions must be taken due to the potential for skin and respiratory irritation from the fibers. Wearing protective gear during installation can mitigate these risks and ensure a hassle-free experience.

Durability

Rigid Foam Insulation

Rigid foam insulation showcases exceptional durability, thanks to its closed-cell configuration which imparts mechanical strength and impermeability to water vapor. This characteristic ensures both lasting performance and minimal maintenance, especially when applied in environments exposed to the elements.

With adequate protection against UV exposure, rigid foam can maintain its insulative properties over decades, making it a durable solution for structural and thermal insulation needs in diverse settings.

Fiberglass Insulation

While fiberglass insulation is reasonably durable, its effectiveness can degrade over time if exposed to moisture or compressed. When properly installed and maintained, fiberglass can function effectively for numerous years, providing a resilient barrier against heat transfer.

Its physical properties can be enhanced with the application of vapor barriers and proper sealing, protecting it from environmental factors that could diminish its performance, thus extending its lifespan and efficiency.

Impacts on Air Quality

Rigid Foam Insulation

Rigid foam insulation generally has a minimal impact on indoor air quality, especially when properly installed and sealed. Modern formulations are designed to limit off-gassing, and closed-cell configurations prevent the release of particulates into the surrounding environment.

However, during installation, care should be taken to ensure that adhesives and sealants used do not emit volatile organic compounds (VOCs), which could compromise air quality if not appropriately managed.

Fiberglass Insulation

Fiberglass can negatively impact indoor air quality if not handled with care during installation, as small fibers and dust can become airborne, causing respiratory irritation. Sealed and unpackaged properly, these risks can be substantially reduced.

The use of encapsulated fiberglass batts or boards with vapor barriers can mitigate the escape of fibers and improve overall air quality within a building, ensuring a healthier living environment.

How to Choose Rigid Foam vs. Fiberglass Insulation

When selecting between rigid foam and fiberglass insulation, consider factors such as location climate, budget constraints, and specific insulation needs. Rigid foam is preferable for high-performance applications requiring minimal space utilization and superior moisture resistance.

Conversely, fiberglass presents an economical solution for standard residential applications with moderate thermal performance needs. Evaluating the longevity, install intricacy, and potential energy savings of each option is essential in making an informed decision aligned with your insulation goals.

Summary of Main Points

| Aspect | Rigid Foam Insulation | Fiberglass Insulation |

|---|---|---|

| Material Composition | Closed-cell polyurethane or polystyrene | Glass fibers woven from sand and recycled glass |

| Applications | Structural, thermal insulation, foundation, and wall sheathing | Residential, walls, attics, and crawl spaces |

| R-Values | 3.8 to 8.0 per inch | 2.2 to 3.8 per inch |

| Cost | Higher initial cost with long-term savings | Lower upfront cost, suitable for large areas |

| Installation Difficulty | Requires skilled labor for precision | Easy to install, suitable for DIY projects |

| Durability | Highly durable, closed-cell provides strength | Reasonably durable, affected by moisture and compression |

| Impact on Air Quality | Minimal if handled correctly | Potential risk from fibers, mitigated by proper installation |